Handmade Chocolates Gifts of Boxed Chocolate Holiday Gifts How to Order About Us

Caramel / Toffee

Dipped Nuts

Dipped Fruits

Dipped creams

Truffles

Chocolate Bark

Candy Canes

Boxed Chocolate

Holiday Gifts

How to Order

Melli

Chocolates LLC

814 Riverside Drive

Fort Atkinson, Wi 53538

Phone :

904/689-9920

mellichocolates@gmail.com

|

Candy Cane Pulling Tradition... |

||

|

|

|

|

Here is a glimpse into how |

||

| First Joe prepares a water and sugar mixture that is heated up to 300º F. This mixture is then poured onto a large marble slab where it is "flipped" and allowed to start cooling. As it reaches a cooler temp (a certain consistency) flavors are added in by a process similar to "kneading bread". After the flavors are fully blended in, the mixture, which is "amber" in color, is cut into pieces (usually three such as red, white & green) one for each color you wish to have. |

||

| One piece, if white is to be one of the final colors, is taken and "thrown" onto a stainless steel hook where Joe pulls and twists the mixture until the amber color turns white. This process is a lot like "pulling taffy". As you notice in the picture Joe needs to be wearing gloves from this point on in the pulling process for the cane mixture is still between 200º and 300º F. |

|

|

| Add Color & Twist | ||

|

The white piece Joe has just finished is now placed on the marble slab and shaped to look |

||

| Once the loaf is stripped it can now be pulled and twisted to create the size you would like (Joe stays with 6, 12 or 24 inches generally). The smaller sizes are done first and as the loaf cools larger sizes are pulled. |

|

|

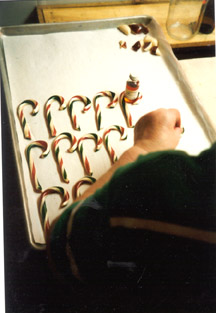

| Shape & Cool | ||

| Joe has now pulled and twisted the loaf into small medium and large stick like pieces. He then hands the "sticks" to Dee, his pulling helper, and she proceeds to place them onto paper lined trays. Once placed on the trays they are left in there stick form or the hook is added. The trays are then left to cool for a few hours and then the canes or sticks are individually wrapped and labeled. |

|

|

| Time to Taste The Finished Candy... | ||

|

|

||

©2005 Melli Chocolates All Rights Reserved